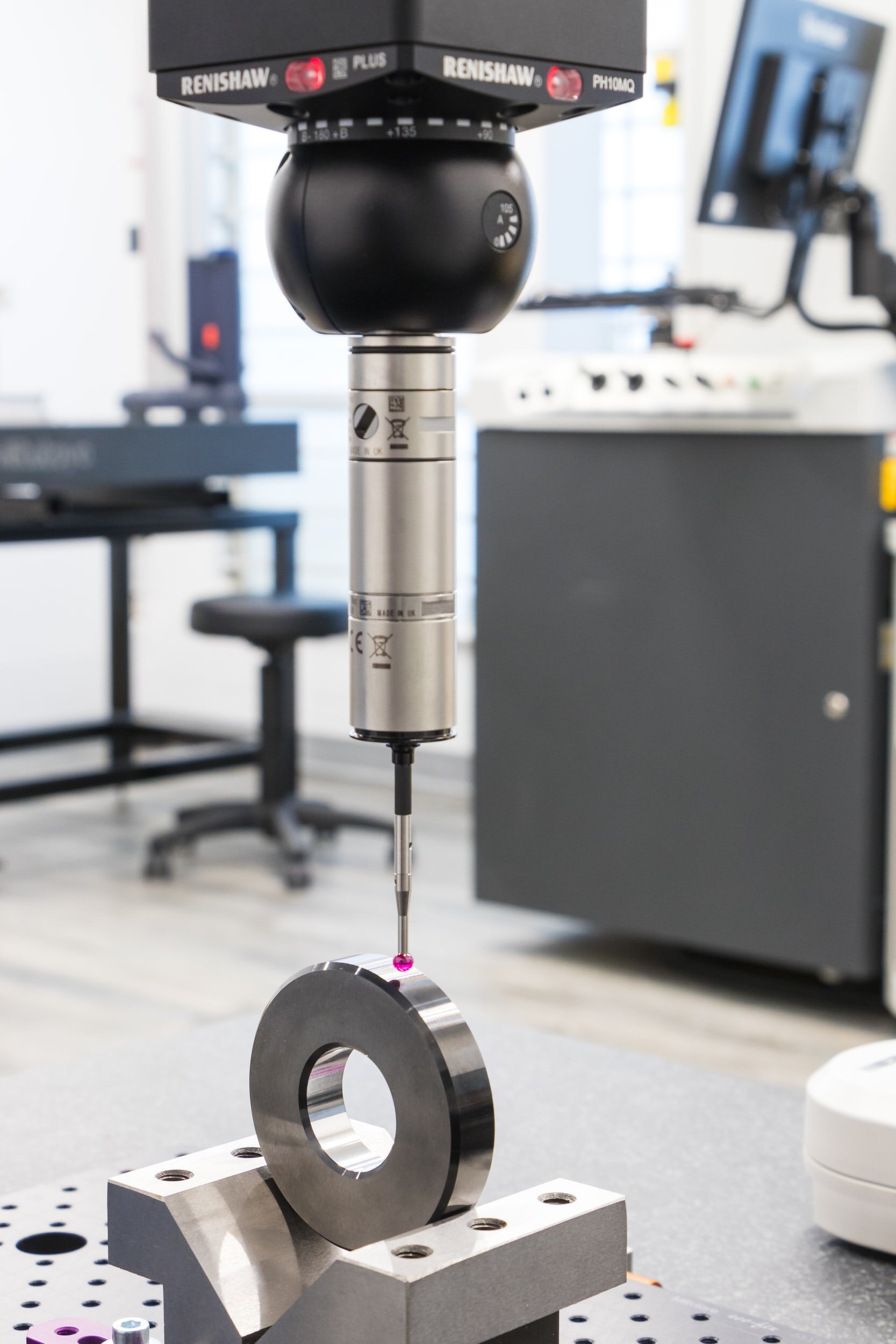

Inspect.

Quality Engineer

Summary of Functions:

Responsible for ensuring procedures and processes comply with internal and customer requirements. Identify internal and external quality issues and implement ways to prevent and improve those issues.

Major Duties and Responsibilities:

Participates in the development of Corrective Action responses and is capable of performing Root Cause Analysis (5 Why’s) and 8D Problem Solving.

Conduct PPAP’s (Production Part Approval Process)

Write control plans and frozen processes for internal and external traceability.

Work with Quoting Dept. to make sure routings are correct and up to date.

Determine what, if any new measuring devices and tools are needed for new job quotes.

Keep track of internal and external scrap and implement and enforce ways to reduce.

Oversee inspections of production runs ensuring they are performed and correct.

Performs other quality control functions as necessary or as requested.

Responsible for calibration of inspection and measuring equipment and coordinates the calibration system.

Responsible to maintain the 6 S’s in the quality lab.

Wage commensurate with experience + Benefits*

Organizational Relationships:

Reports directly to the Quality Manager. Works closely with Production and Quoting

This position also provides backup to Quality and Plant Managers

“AWAYS DELIVER MORE THAN EXSPECTED”

-Larry Page